CMYK in Printing, How It Works and Why It’s Used

CMYK stands for cyan, magenta, yellow and key (black), and is known as the four-color printing process. It is distinct from RGB, the other standard color model and is used in a different way. This article will delve into the basics of CMYK color model printing and explain how this differs from RGB, and when it would benefit you to use each color model.

By learning more about CMYK, you can grasp key factors that will enable you to create print materials with perfectly translated colors across different print media.

What Is CMYK?

CMYK, as we mentioned above, stands for the four colors used in printing ink: cyan, magenta, yellow and key (or black). It is a subtractive color model, which refers to the way these colors each reflect or absorb light. In a subtractive color model, colors are created by subtracting certain wavelengths of light. And, when any of these four colors are combined, together they subtract various parts of the light spectrum. The result is the perception of certain colors.

In printing, the four colors can be applied to a white surface to produce a very wide range of colors. For example, Cyan absorbs red light, so blue and green light is reflected. This means that when cyan is added to the page, it subtracts red so shades of green and blue are created.

Each of these four colors absorbs and subtracts different colors and thus reflects different colors. The way these four colors are combined determines each color seen in a final printed work.

How CMYK in Printing Works

CMYK printing is a unique process that produces excellent color results. To create full-color images, printers use tiny dots of cyan, magenta, yellow, and black inks, carefully overlapping and mixing them to achieve the desired colors. This technique allows for a broader range of hues beyond only the primary colors.

During printing, these minuscule dots can be so densely arranged that they can appear as solid colors. By adjusting the quantity and overlap of these dots, printers can reproduce a wide spectrum of colors and that results in high-quality prints. Larger, closely spaced dots create darker areas, while smaller, more spaced-out dots result in lighter shades. By varying dot density and placement, printers can closely match the colors of the original image.

Why Choose CMYK for Printing?

There are some clear advantages in printing with CMYK over printing with RGB, which stands for Red, Green, Blue. When creating a design for a screen, RGB colors will always be brighter, as these colors are created for digital images. But for printing, CMYK can reproduce colors more accurately. By mixing different proportions of the cyan, magenta, yellow and key (black), a wide enough range of colors is possible to give superior results.

CMYK is also known for consistency in printing. Even if you need to print multiple runs, the finished product will turn out uniform. This is helpful for projects like printing branding or marketing materials, where consistency is essential.

All these reasons have helped make CMYK the industry standard for color printing. And, since it’s so widely used, most commercial and professional printers are accustomed to working with CMYK color models.

CMYK vs RGB

RGB color mode combines red, green and blue to create colors. By contrast to CMYK, RGB is an additive color model, which means all colors start as black, and are changed as red, green or blue light is added on top to layer. When layers of these colors of light are mixed together at the same intensity, the result is white. RGB allows for very bright colors.

In RGB color, you can change saturation and shades by changing any of the three colors. Since these changes are controlled digitally, they result in differences in the way light is seen on a screen. RGB colors will always appear brighter than CMYK colors for this reason.

CMYK Ink Types and Matching Colors

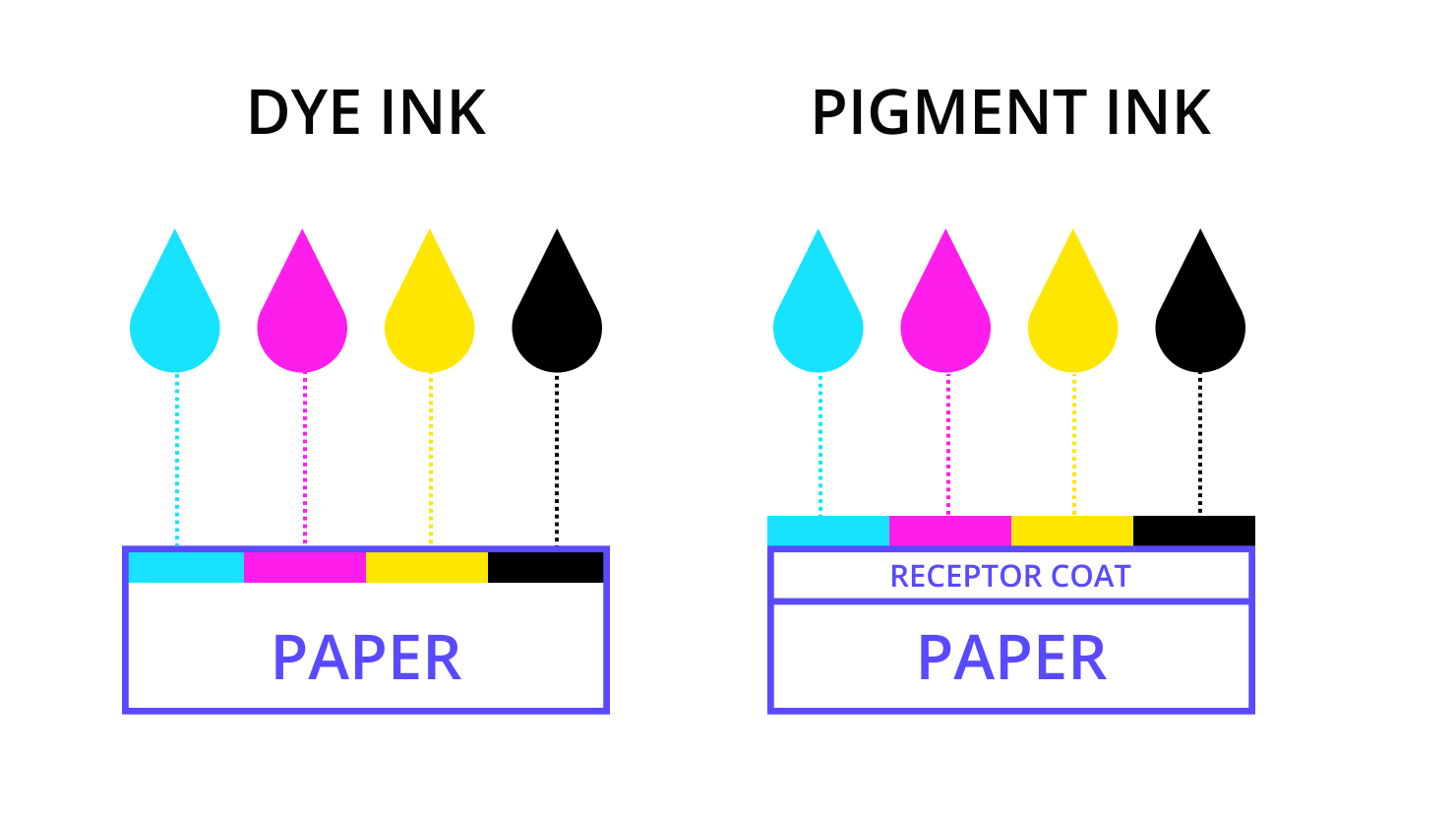

There are two main types of ink used in CMYK printing: dye-based and pigment-based.

Dye-Based Ink

The type of ink you choose depends on the specific project. Dye-based ink is made of color pigment that is dissolved in water. These are the average inks found in most inkjet printers and are the less expensive option of the two inks. Printing with dye-based ink will be vibrant and true to color and is great for images that are used indoors, like posters or fine art photography.

Pigment-Based Ink

Pigment-based inks contain pigment that is suspended in water and is insoluble, making it more waterproof. Pigment-based inks are more expensive to use and have a very specific application. These inks are great for outdoor displays or heat transfer paper. They are fairly stable and UV resistant, though with enough sun exposure, they will fade over a long period of time. They can appear more muted than dye-based inks.

Spot Colors

As accurate as CMYK colors can be in printing, there are instances where an exact match is needed in print and it cannot be achieved by mixing the four colors. In these cases, printers use what is called “spot colors” or Pantone colors. Pantone offers a standardized color matching system, so artists can select and specify precise colors, regardless of the printing method. By incorporating Pantone colors into the CMYK workflow, designers can achieve higher color accuracy and maintain consistency. Spot colors are one more tool in the designer’s toolbox that allows for excellent color matching and high-quality printing results.

Conclusion: CMYK for Excellent Prints Every Time

A solid understanding of CMYK printing is essential for artists and designers to be able to produce high-quality printed products from their creations. By knowing the difference between CMYK versus RGB color modes, you can choose which color mode to work with, based on the finished product you aim to create.

Using CMYK color mode for printing offers several advantages, especially the ability to reproduce colors more accurately and consistently, making it the industry standard for color printing. And, the choice between dye-based and pigment-based inks allows for customization of your projects–offering unique qualities with each type.

To ensure an exact color match, even beyond the capabilities of CMYK, Pantone colors, or spot colors, are another valuable tool. Spot colors enable designers to reach greater color accuracy when a perfect match is needed in printed materials.

Whether you’re new to the world of print design or a seasoned color palette master, mastering the nuances of CMYK printing will help you achieve professional results in printing.